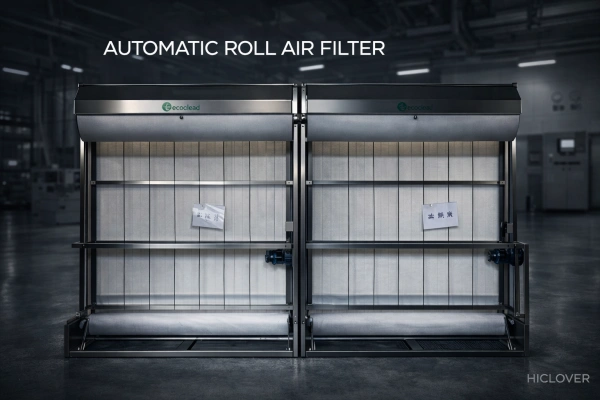

Industrial Roll Air Filter Factory: Inside the Making of Automatic Roll Air Filter Solutions

Industrial Roll Air Filter Factory: Inside the Making of Automatic Roll Air Filter Solutions

Selecting an Industrial Roll Air Filter Factory is not only about sourcing equipment; it is about ensuring long-term reliability, automation quality, and consistent performance in demanding environments. In industries where dust, fibers, and airborne particles are continuous challenges, the manufacturing approach behind an Automatic Roll Air Filter directly determines how well the system performs over its entire lifecycle.

HICLOVER operates as a specialized factory focused on roll-type air filtration systems designed for continuous industrial operation rather than short-term use.

What Defines a True Industrial Roll Air Filter Factory

An industrial roll air filter factory must go beyond basic assembly. It must integrate mechanical design, automation control, and application-specific engineering into a single, reliable system.

At the factory level, HICLOVER designs automatic roll air filters around continuous media advancement. As dust accumulates and airflow resistance increases, the filter media advances automatically, maintaining stable airflow without manual intervention. This factory-driven system design ensures consistency across production and predictable performance in the field.

Factory Design Philosophy Behind HICLOVER Systems

HICLOVER’s factory focuses on practical engineering for real operating conditions. Instead of optimizing for short-term test results, the manufacturing process emphasizes durability and simplicity.

Key factory-level design priorities include:

-

Robust structural frames for long-term industrial use

-

Reliable drive mechanisms for smooth media advancement

-

Control systems based on actual dust loading

-

Flexible dimensions to match different airflow requirements

This approach allows the automatic roll air filter to function reliably in harsh environments where downtime is costly.

Industrial Applications Supplied by the Factory

As an industrial roll air filter factory, HICLOVER supplies roll-type filtration systems across multiple sectors where dust control directly affects operational stability.

Power generation and engine intake air

Generators depend on clean intake air to maintain efficiency and reduce wear. Factory-built roll filters provide continuous protection with extended service intervals.

Mining, cement, and bulk material handling

High dust concentrations quickly overwhelm conventional filters. Roll-type air filters manufactured for industrial duty handle heavy particulate loads without rapid clogging.

Industrial HVAC and process ventilation

In factories and processing plants, roll air filters serve as durable pre-filters, reducing the burden on fine filtration stages.

Containerized and remote installations

Factory-assembled roll filters offer compact integration and autonomous operation, ideal for sites with limited maintenance access.

Automation Integrated at the Factory Level

Automation is not added later; it is built into the factory design. HICLOVER integrates differential pressure monitoring and automated media advancement during manufacturing, ensuring consistent performance across installations.

This factory-level automation delivers:

-

Stable airflow under variable dust conditions

-

Reduced maintenance labor

-

Predictable operating cost

-

Improved system uptime

For industrial users, this level of automation is essential rather than optional.

Why Factory Capability Matters More Than Product Labels

Many filters perform well when new. Fewer continue performing after months or years of heavy dust exposure. An industrial roll air filter factory must design for lifecycle performance, not just initial specifications.

By controlling design, fabrication, and system integration in-house, HICLOVER ensures that each automatic roll air filter meets the same industrial standard, regardless of application.

More information about roll-type air filtration systems and factory-produced solutions can be found at https://www.cloverfilter.com/, where industrial applications of automatic roll air filters are presented in detail.

A Factory Built for Long-Term Industrial Demand

HICLOVER’s industrial roll air filter factory is structured around continuous operation requirements. Each system is built to withstand dust, vibration, and long operating hours while minimizing maintenance dependency.

As industries demand higher uptime, automation, and predictable costs, factory-produced roll-type air filtration is becoming the preferred foundation for modern industrial air management.

Résumé (Français)

L’usine de filtres à air à enroulement industriel HICLOVER conçoit des solutions de filtration continue, fiables et automatisées pour les environnements industriels exigeants.

Resumen (Español – México)

La fábrica Industrial Roll Air Filter de HICLOVER ofrece sistemas de filtración automática y continua, ideales para aplicaciones industriales de alta exigencia.

Resumen (Español)

HICLOVER es una fábrica confiable de Automatic Roll Air Filter, especializada en soluciones industriales de filtración continua y automatizada.

2026-01-05/10:00:24